Ten-Year Development Project Results in potential for First Mosquito Adulticide Based on Fermentation Technology

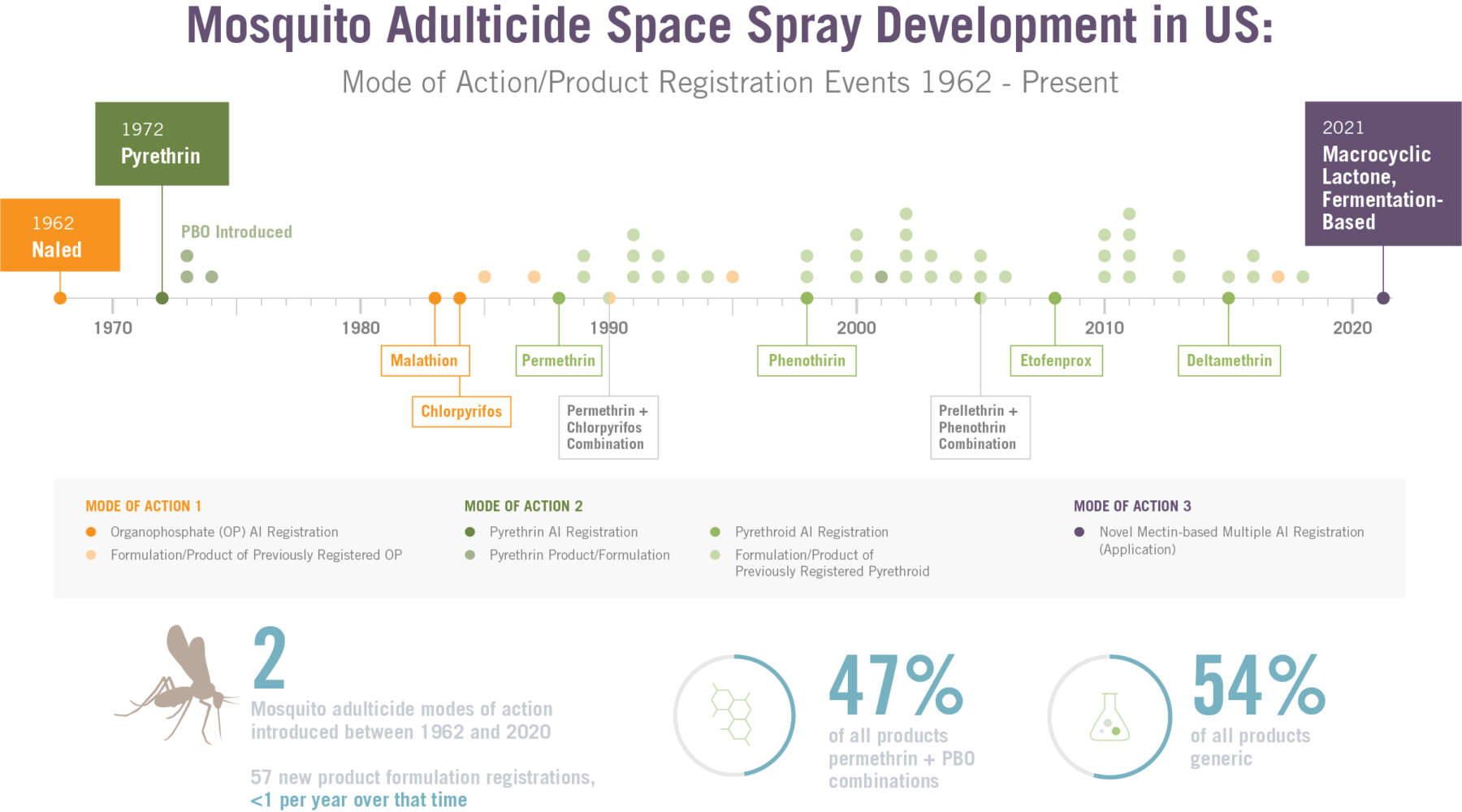

An Experimental Use Permit (EUP) application has been submitted to US EPA for aerial application of a new adulticide targeting pyrethroid-resistant mosquitoes. The breakthrough represents the first novel adulticide mode of action in the US in nearly 50 years and features a combination of three active ingredients in the first-ever mosquito adulticide space spray based on fermentation technology.

The technology was developed over a ten-year period by a cross-functional team of experts at Valent BioSciences (VBC), a global leader in biorational fermentation technologies for public health, forest health, and agriculture. The full registration dossier for the technology was submitted to US EPA in August and the VBC is awaiting review of the package submission.

The innovation is the first to leverage the power of macrocyclic lactones in mosquito vector control. Macrocyclic lactones such as ivermectin have been used for more than 40 years as drug therapies in human and veterinary applications. The new mosquito adulticide combines the macrocyclic lactone abamectin with an organic fatty acid and the Class 2 pyrethroid fenpropathrin.

Designing a Novel Mode of Action: A Ten-Year Team Effort

VBC’s Mosquito Adulticide (MAP) project traces its beginnings the 2009 American Mosquito Control Association annual meeting in New Orleans. A presentation there by researchers from the US Centers for Disease Control and Prevention (CDC) suggested the possibility of using plant-derived compounds exhibiting unique modes of action as public health pesticides. The potential for these compounds to be produced through fermentation and employed in control of pyrethroid-resistant mosquito populations struck a nerve with the VBC pipeline development team who initiated evaluations of the compounds as mosquito adulticides. Pyrethroid resistance has been identified around the world as one of the most serious threats to vector-borne disease management. Mosquitoes vector deadly and debilitating diseases such as malaria, West Nile virus, dengue, Zika, and others.

Partners in Progress Series

While VBC’s evaluation of the compounds did not lead to their development for mosquito control, the team remained focused on a solution to pyrethroid resistance. A subsequent chance meeting at an industry conference brought VBC personnel face-to-face with a team of innovators who were focused on leveraging a carefully designed ratio of specific organic fatty acids (carbon chains of 8, 9 and 10; C8910) to operate as an insecticide and repellant for livestock. After comparing notes, the two companies signed a materials transfer agreement and VBC officially launched the MAP project in 2011.

Working in favor of the VBC team were several important factors: expertise in fermentation technologies, expertise in organic chemistry, noted expertise in formulation science, and proven leadership in innovative field research in the public health space.

As the team discussed design goals, the group decided to innovate without the assistance of the industry’s go-to mosquito adulticide synergist piperonyl butoxide (PBO) in the product. PBO is commonly used with pyrethroids to boost the activity of mosquito adulticides to address pyrethroid resistance, but has come under fire recently by regulators.

Initial project work was limited to combinations of different fatty acid ratios and pyrethroids, with a design goal of achieving 95% mortality in both susceptible and pyrethroid-resistant populations. A key challenge in the work was that not all resistance mechanisms are equal. Different mosquito species (disease vectors) have adapted to pyrethroid use in different ways. The goal was to build a tool that would be effective against each one.

Work was slow, but deliberate. Despite the team’s best efforts, phase one of the project came to a close. While there had been noteworthy successes leading to a US Patent, the design goals simply could not be met with a combination of a pyrethroid and (C8910) alone. No combination proved powerful enough to achieve the necessary mortality against ALL types of resistant mosquitoes. At one point, it was suggested that the team compromise on the no-PBO requirement. Ultimately, the idea was rejected because it would have restricted the innovative possibilities for the technology platforms that were being developed and thus ultimately lessen the long-term value of the product’s potential to the vector control community.

“We launched this project to develop something that broke the bounds of possibility to deliver something very specific to the global vector control community,” says Jason Clark, Global Business Manager. “Pyrethroid resistance is a global phenomenon, and while PBO is highly effective, we felt we needed to pave a different path. As tempting as it might have been to include it, it just didn’t make sense to bring a new technology platform to the market that potentially could face a regulatory limitation, particularly in areas such as California where pyrethroid resistance is pronounced and PBO is facing challenges with all of the agricultural production that takes place there. We wanted to think different.”

MAP was down, but not out. It was at this same point in time (2016) that a foundation of literature had begun to emerge surrounding the potential for ivermectin (a macrocyclic lactone) as a mosquito control intervention. As early as the late 90s, it had been observed that in areas where ivermectin had been used for onchocerciasis control (particularly West Africa), the incidence of malaria was uncharacteristically low1. Several subsequent studies had been published confirming that ivermectin – ingested and present in blood – did exhibit strong activity against adult mosquitoes (see New MoA Success Drives Provocative Research). Perhaps macrocyclic lactones offered potential for MAP.

About Macrocyclic Lactones:

Macrocyclic lactones (avermectins and milbemycins) are a class of naturally derived compounds based on the soil microorganism genus Streptomyces. Manufactured through fermentation, macrocyclic lactones demonstrate powerful activity against parasitic worms and multiple insect species. The most widely used macrocyclic lactone is the therapeutic drug ivermectin, known for its prominent role in an onchocerciasis (River Blindness) intervention through efforts organized by the World Health Organization as well as more than 40 years of application as a veterinary drug.

Macrocyclic lactones act upon target sites within helmintic and insect nerve and muscle cells, blocking transmission of electrical activity. This leads to hyperpolarization of neuromuscular systems, resulting in paralysis.

Since the neuromuscular systems in humans and other mammals lack the same glutamate-gated channels as the worms and insects, macrocyclic lactones have limited mammalian toxicity. This has allowed compounds such as ivermectin to be safely ingested by humans and other mammals as a means to control parasites. Abamectin, another member of this class, was introduced as an agricultural insecticide/miticide in 1985.

Project Evolution

Although the research seemed promising, there were undeniable challenges surrounding the use of ivermectin as an intervention to combat mosquito-borne disease. The primary factor was that the residual for ivermectin in mosquitoes was relatively short – somewhere between one and two months. This posed several barriers including the cost, logistics, and behavioral modifications that would be necessary to use ivermectin as a drug for mosquito control. Getting at-risk people to take two doses of ivermectin per year had been problematic in onchocerciasis efforts. The notion of far more frequent dosing to use ivermectin as an ingested therapy seemed unrealistic.

Still, the development gave VBC another idea. Would it be possible to get a macrocyclic lactone inside a mosquito through different means? Knowing ivermectin was produced via fermentation further cemented with the pipeline development team this was a research path to invest in. The possibility became the pivot point in the project: MAP 2.0.

“The fact that our earliest efforts had come up short was disappointing,” says Clark. “But at the same time, there were all of these really exciting publications coming out indicating a mosquito would bite somebody and then the mosquito would die. It made us think that perhaps we could bite back.”

Dr. Ben Belkind was a VBC Senior Formulations Scientist working on the project at the time.

“I told the team I had never worked with ivermectin specifically, but I had done extensive work with abamectin – another macrocyclic lactone – at an earlier point in my career. I knew that abamectin was registered with EPA as an agricultural pesticide because my work had focused on abamectin as a potential control agent for root knot nematode. It was promising research, but ultimately the opportunity was not pursued.”

The team figured that if ivermectin was effective on adult mosquitoes, it seemed reasonable abamectin would be as well.

“As a fermentation-based company, we’re trained to understand how organisms grow and to select organisms that could produce compounds that might be valuable to public health, forest health, and agriculture. “We’ve had a lot of experience in this area,” Clark says. “But there’s no doubt that in this case, we were trying to bridge a divide unlike anything we’d ever tackled before.”

For Belkind, the most daunting challenge was the molecular weight of the abamectin compound. Relatively speaking, the molecules are about three times bigger than existing adulticides. For the idea to work, the VBC team would have to figure out a way to get abamectin inside the mosquito.

In 2016, the team asked Belkind if he thought he could find a way to get it past the mosquito cuticle. He said it was certainly worth a try.

“I remember very clearly the first time we discussed it,” Belkind laughs. “I thought to myself, ‘this is not just outside the box, it’s three miles away from the box.”

Undeterred

While the initial stages of the MAP project had been unsuccessful in identifying a combination technology that controlled all types of pyrethroid resistance in mosquitoes, the team had learned some interesting characteristics about (C8910). The fatty acid had already been registered as a mosquito repellant, and the team’s early work had confirmed that it had a synergistic effect with the pyrethroids they were testing. It was simply that none of the tested combinations proved powerful enough to achieve the mortality defined by the design goals against all mosquitoes.

But (C8910) had other qualities Belkind could build on.

“These fatty acids have a sort of duality that is built into their chemical structure,” Belkind explains. “The molecules have a polar end and a non-polar end. Quite often, when you need to transport an active ingredient, these molecules have properties that enable you to find the “soft spot” in cell membranes. And so if they are structured properly, on one end you could say they “like” the active ingredient and on the other end they like the membrane – or parts of the membrane – where there are certain susceptible areas in the cuticle. We thought this might provide us with an enhanced active ingredient transport into, or toward, the active site.”

As Belkind set about on this new path, Peter DeChant (VBC’s Global Technical Manager working on the project at that time) was changing gears also. DeChant had been driving research on the application side of the MAP project. As with Belkind, DeChant had made some meaningful progress. DeChant is perhaps best known for leading VBC’s US field development of the WALS®application strategy, the company’s award-winning approach for treating mosquito larvae in difficult to find or access habitats. It was this deep experience in droplet sizing, aerodynamics, and sprayer calibrations – combined with learnings from his initial work with (C8910) + pyrethroid combinations – that fueled new delivery possibilities for these novel product concepts.

Additional resources, in the form of new team members, provided yet another boost to the team. Dr. Banu Kesavaraju joined the VBC Public Health group in 2014 as a Technical Development Specialist, with a strong background in mosquito biology. Late in 2015, VBC also brought on Dr. Mayur Soni as a full-time formulation scientist. Soni had been working with Ben Belkind as a temporary lab assistant for the year prior, and was responsible for formulating prototypes for MAP and delivering them to DeChant for testing. Over the course of the next few years, Soni and Kesavaraju would step in for Belkind and DeChant, both of whom would retire but continue working on MAP as consultants.

These additional resources proved vital in realizing the project’s vision.

In the lab, Soni was responsible for preparing a new stream of prototypes that brought together now three active ingredients into a single platform: C8910, abamectin, and the new-to-market pyrethroid fenpropathrin.

“It was very exciting to be working right away on such an important project,” Soni recalls. “As an assistant, I had just been formulating prototypes according to Dr. Ben’s requirements. Then I became a full-fledged member of the team and started participating in all of the discussions and white-boarding sessions. I began to learn all about the industry and realized the full magnitude of what we were undertaking, and what it might mean if we were successful.”

While Soni and Belkind toiled away on the challenge of finding just the right combination of actives, DeChant and Kesavaraju were at work with technical field partners on a new project of their own: Building an elaborate, customized wind tunnel to meet the efficacy/application testing requirements of MAP 2.0.

DeChant says that after their initial work, it became apparent the team needed some way to test resistant and susceptible mosquitoes side by side in the same spray cloud. He says there are wind tunnels in operation around the world but they are mostly single tunnels fashioned out of heating duct material, and only about eight inches wide. That setup wouldn’t work for the kind of testing the team needed to do.

Double Wide

DeChant and Kesavaraju wanted to get exactly the same dose of material to multiple kinds of mosquitoes at the same time. The solution was to begin constructing a much larger tunnel that allowed delivery of material across four groups of four cages, positioned side by side, at four different distances from the sprayer. The tunnel also allowed testing spray volumes which matched the range used in outdoor mosquito space sprays.

“The prototypes we were getting from Soni started getting better and better,” Kesavaraju says. “Our threshold for replicating trials quickly moved up to 70% efficacy. Then 85%. And as we started dialing in on the formulation, the amount of material we needed to achieve these mortality rates kept getting smaller and smaller. Pretty soon we were trying to load less than one milliliter of material into an industrial sprayer, which is almost impossible. So we equipped the tunnel with some nozzles they use to fog food storage warehouses, with pyrethroids, to guard against insects.”

Banu had also brought the team his considerable experience in raising and maintaining insect colonies, done as part of his graduate studies.

“From my perspective, getting mosquitoes for these trials might have been our biggest bottleneck,” he says, “Raising and maintaining a colony of resistant mosquitoes isn’t easy. If you put these mosquitoes in the lab, the resistance goes away very quickly. There needs to be a selection force, which in the case of resistant mosquitoes, is the pesticide. If you have a bunch of mosquitoes lying around in the lab, and they are competing with each other for food and other resources, having resistance to a particular pesticide is not a benefit like it is in the field. The resistance mechanism requires some of the mosquito’s energy, so those mosquitoes aren’t very efficient compared to those that are just tolerant or those that are susceptible. The more efficient ones will start to take over the colony and within four or five months you won’t have any resistance at all.”

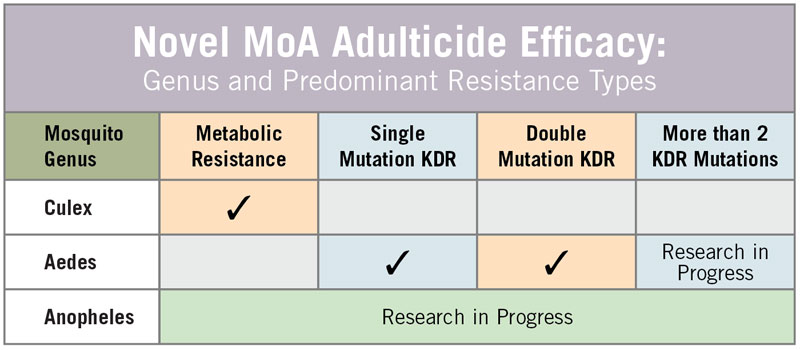

Adding to the challenge of sourcing mosquitoes were complexities behind pyrethroid resistance among different genera. Not all resistance mechanisms are the same (see sidebar). In general terms, Culex species have adapted to pyrethroids primarily through a mechanism called metabolic resistance, while Aedes species primarily exhibit a difference mechanism called Knockdown Resistance (KDR). Anopheles mosquitoes demonstrate both types. Adding to the complexity is that there are multiple KDR mutations, and each would require individual testing.

To overcome this challenge, Kesavaraju had to seek out, contact and forge agreements with numerous sources including multiple labs and universities who provided a year-round supply of “just-in-time” mosquitoes or eggs. Some were raised in the lab, others were colonies raised from mosquitoes caught in the wild, all depending on the season and target species. At times it was a logistical quagmire, but it was necessary to achieve the goals of the project: effective against all types of pyrethroid-resistant mosquitoes.

Not All Resistance is Created Equal

Development of an effective new mode of action adulticide for pyrethroid-resistant mosquitoes was based on the premise that the resistance mechanism is not the same for all mosquito genera.

The Metabolic Resistance mechanism is a mutation that promotes the production of enzymes the mosquito uses to process the pyrethroid out of its system. This type of mechanism is common to Culex species including Culex pipiens.

Knock Down Resistance (kdr) is a mechanism whereby the mutations block binding of the insecticide to sites on the sodium channel within the insect, thus allowing the mosquito to retain its ability to fire an action potential. This type of resistance is commonly associated with Aedes species including Aedes aegypti.

A key design goal for VBC’s new adulticide was that it achieves a high level of mortality against both types of resistance, as well as against pyrethroid-susceptible populations.

This dogged work was taking place concurrently. Back in the formulations lab, Belkind and Mayur were busy creating new prototypes for testing, each with different ratios of the actives.

Hundreds of Prototypes

“Formulations work can be tedious and counterintuitive,” says Belkind. “Suppose you start out with two compounds and arbitrarily choose a one-to-one ratio of the actives you’re working with. You may not see any effect. But if you chose a 1 to 10 ratio, or a 10 to 1 ratio, or somewhere in between – suddenly you might discover a space where there is considerable activity. We needed a high level of activity across multiple species and multiple types of resistance. It took quite a bit of time and patience.”

Clark says the interaction between Belkind and Mayur in the lab, and DeChant and Kesavaraju in the field, was something to witness.

“It’s a real mental exercise when you start thinking about all of the objectives and all of the variables we needed to account for with MAP,” says Clark. “First you are dealing with all of these kinds of resistant populations. It wasn’t as if we had this one active and we needed it to do just one thing. We had multiple actives that all had to have their own pathway to their specific target. They had to get there, perform when they got there, and all had to “play nice” in one single formulation along the way.”

It wasn’t just the active ingredients that played a role. The physical and functional demands of the product required that an entirely new inert system be developed as a carrier. The inert system proved to be just one of several novel aspects of the final formulation.

“In addition to the effect on multiple targets, we had to be thoughtful of the physical properties of the material,” Mayur says. “The viscosity. The specific gravity. In some applications it would have to be sprayed from the ground to be delivered to the target. In others it would have to be sprayed from aircraft and make it to the target. It couldn’t degrade once it became airborne. It had to have storage stability all the way from -20F° to 110F°. These were all non-negotiable requirements that were a critical part of the testing, above and beyond the mosquitoes themselves.”

The more advanced the work became, the more it became evident to the team that Culex would be the most challenging.

“We started to get good results with the KDR resistant mosquitoes early on,” Kesavaraju says. “Culex was a lot tougher. Culex like to breed in polluted habitats, so they’re already equipped with enzymes that help them digest and process out unwanted materials. We’d had good results with Aedes, but the Culex would get knocked down twelve or sixteen hours then be up and flying around again like nothing ever happened.”

Kesavaraju says that’s where PBO really makes a difference with the industry’s current pyrethroid-based adulticides. PBO really helps an active get past those enzymatic barriers and reach the target site.

Dialing In

As the evolving samples proved more and more effective, it became obvious to Kesavaraju that the amount of active ingredient required in the final formulation was going to be exceptionally low. That made Mayur’s inert system all the more important. The diluent would have to be able to exist in the final formulation with enough volume to make the product practical to use.

“We’d never dealt with anything quite that low before and it required some very skilled formulation work,” he says. “We had to be thoughtful about the limitations of application equipment in the field. Mosquito abatement districts are not running tests in a super-modified wind tunnel, they have to spray out in the real world. Dialing in the low amounts of AI we were using would never work for an applicator, so our new diluent system had to get us the volume we needed.”

In all, Mayur estimates the group tested almost 300 prototypes before they reached their coveted milestone. By that time, the team was focusing almost exclusively on Culex, since strong activity against resistant Aedes had already been shown.

“I remember exactly where I was,” Clark says. “We had a meeting in Minneapolis and when I got back to my room, I saw an email from Banu with the latest data set. I opened it up and saw that we’d crossed the 95% mortality threshold on resistant Culexin our trials. I just stood there for a moment looking at the chart and letting it all sink in. What a feeling.”

That was in March of 2018. Subsequent trials to tweak the formulation and achieve the same mortality with double KDR Aedestook until January of 2019. Research on resistant Anopheles sp. is currently in progress.

Serendipity lies in the domain of the informed

Ben Belkind

A number of patents have been received and are pending as a result of VBC’s work. But the work is not done. In addition to working with the team on the registration process and planning work with cooperating districts in anticipation of an EUP for aerial applications, Kesavaraju must also turn his attention to other aspects of bringing this breakthrough to market.

“How field personnel will be able to use the new material for testing is an important detail that still needs to be worked through,” he says. “The standard bottle bioassays districts use to gauge efficacy aren’t designed for a combination product like this. You cannot separate the actives out and try to elicit the same kind of mortality as you would with a typical bottle bioassay. Each of the actives works differently on different populations. We’re in the process of figuring out how we can collaborate with CDC to develop a new method that fits the way this new product works.”

Looking back, Clark says that he is proud of how the team persevered.

“If you’re going to be on the cutting edge, you have to anticipate setbacks,” says Clark. What I am most proud of is that we didn’t compromise on our design goals and limit our research to just one piece of the puzzle or one part of the problem because other parts were proving challenging. The Public Health community needed and deserved more than that.”

Belkind has a similar take.

“If you just looked at it statistically, the odds for developing such a complex product would be very small – even discouraging, perhaps. But serendipity lies in the domain of the informed. It was the combined expertise of the team that made the difference in this project. I am proud to say I was a part of it.”

1 Mekuriaw, W., Balkew, M., Messenger, L.A. et al. The effect of ivermectin® on fertility, fecundity and mortality of Anopheles arabiensis fed on treated men in Ethiopia. Malar J 18, 357 (2019). https://doi.org/10.1186/s12936-019-2988-3